Hightec works according to the customer specifications to deliver consistently excellent products.

Facilities and Equipment

We use state of the art technology coupled with modern production facilities. Our well-trained technical staffs utilize this to ensure a smooth production process and consistently high-quality finished products. We use multiple unique designs to fit specific customer requirements.

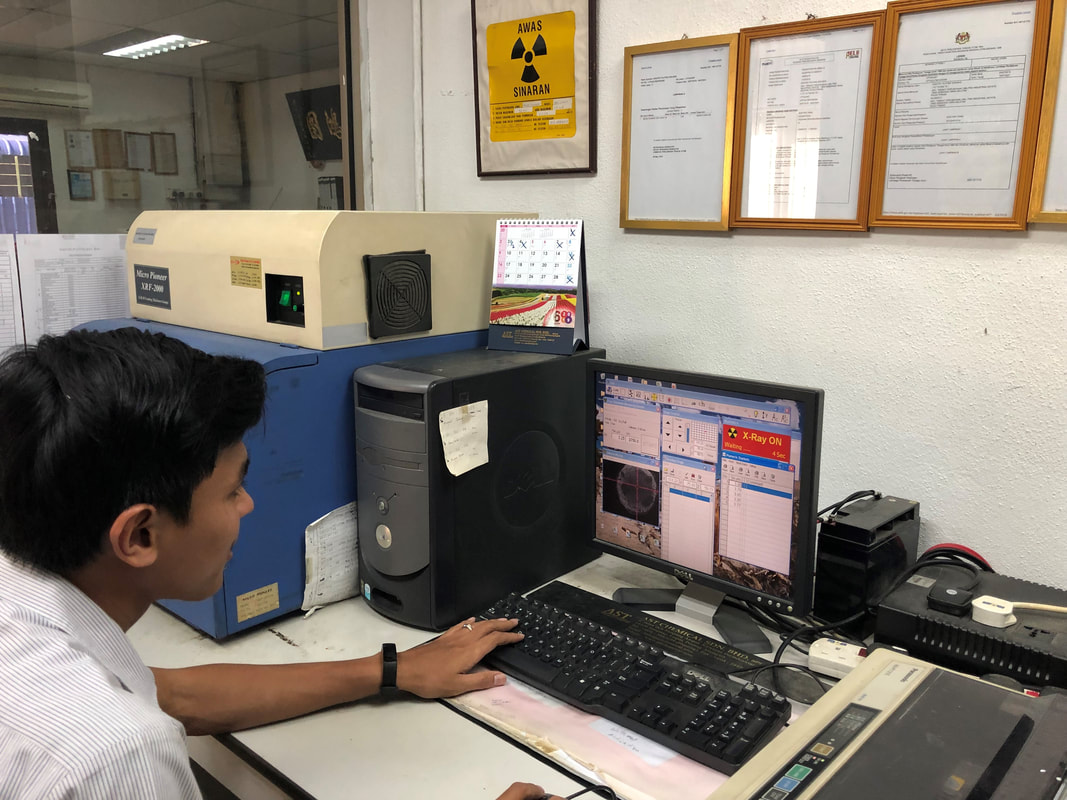

Barrel load sizes, types of plating media, proper rack placement, voltage configurations, electro-chemical formulations, and other criteria are custom-designed per item. These are all pre-tested in our laboratory (supervised by Master's level staff) before mass production begins.

Barrel load sizes, types of plating media, proper rack placement, voltage configurations, electro-chemical formulations, and other criteria are custom-designed per item. These are all pre-tested in our laboratory (supervised by Master's level staff) before mass production begins.

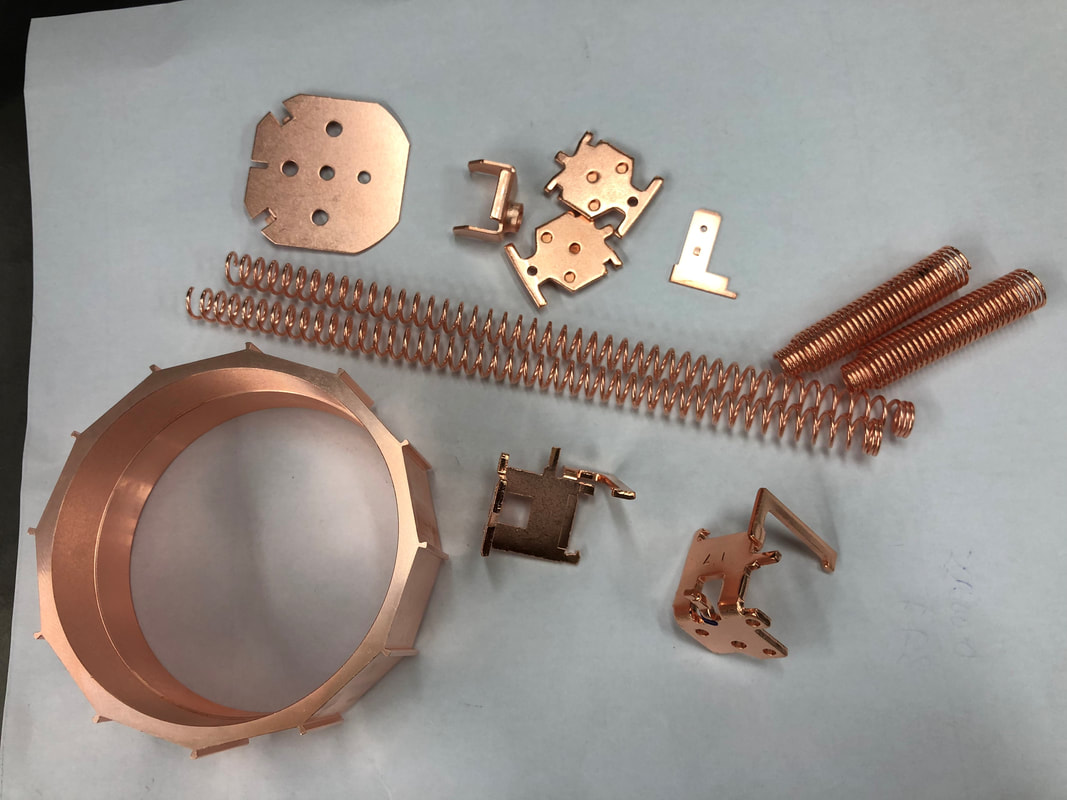

Metal Finishes

We help customers add a layer of quality metal plating for copper, nickel, silver, and tin. Additionally, we provide zinc and manganese phosphating. We specialize in electroplating using the most advanced manufacturing processes for barrel and rack work. We also do electroless nickel plating for the most demanding parts. Multilayer finishes (e.g., copper-tin) are possible for us too.

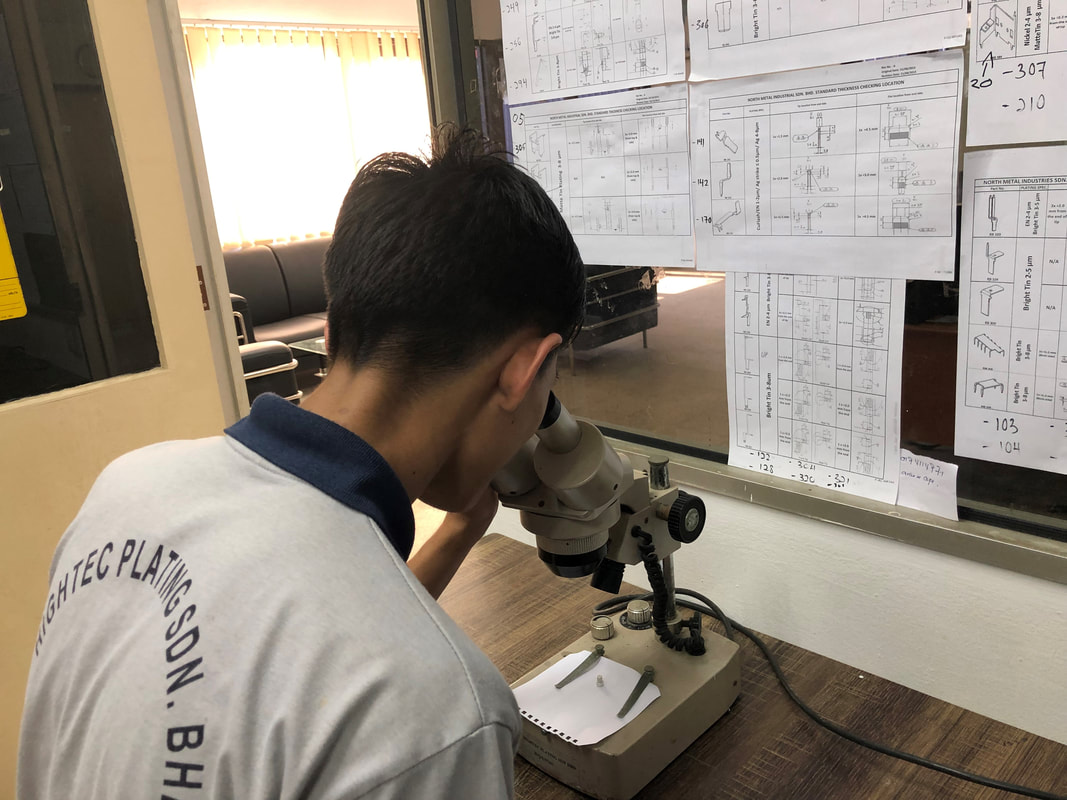

Quality Management

Hightec adheres to a quality control program based on the following elements:

- Incoming materials inspection

- Document control

- Statistical process control

- Quality assurance system

|

Want a quotation? Our sales team is ready to assist.

|